The project involved meticulous organisation and execution of traffic management plans, including MOAs and TGS, as well as hydro excavation to expose services and utilities for service proving. Close collaboration with surveyors facilitated accurate service proving, while careful attention was paid to reinstating surfaces to their original condition.

Client engaged TDG to assist with grease removal using a Class B pump for water blasting. After years of grease buildup in the sediment tank, it was deemed unsafe for the contractor to perform any hot works. TDG entered the confined space and removed all hot work hazards using high-pressure water blasting and emulsified grease down to run back through the treatment plant.

Client engaged TDG to assist with a major sediment removal and rectification works project for multiple On-Site Detention Basins within an Airport in NSW. These OSDs had suffered years of neglect and were contributing to localised flooding in major rain events.

Faced with an extremely challenging culvert, this historic brick arch required precision and caution due to its fragile nature, susceptible to damage if mishandled. TDG Environmental was tasked with cleaning out the culvert chamber, measuring nearly 30m in length and 2m in width.

TDG Environmental was reached out by a local council to clean and clear the blockages at the inlet. The client was also aware that we were unable to clear the blockages without Ultra High-Pressure Water Blasting (UHPWB).

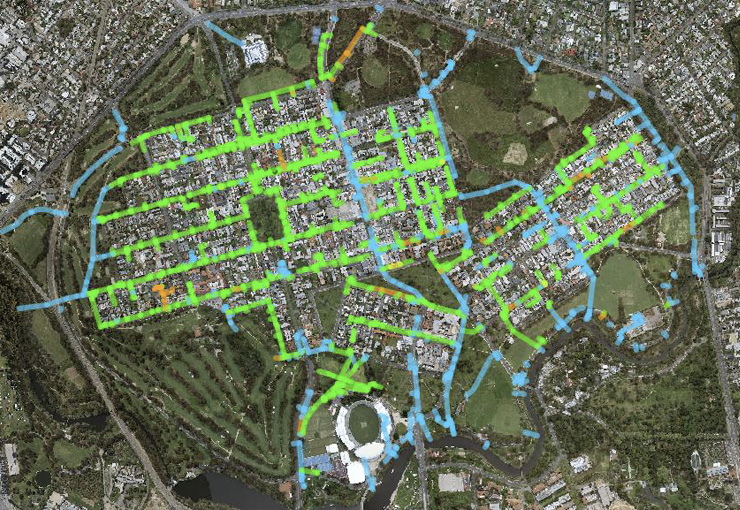

Stormwater Survey, Inspection and Condition Assessment of the entire North Adelaide Storm Water network

TDG’s unmanned (remote operated) dredge is unmatched when it comes to delivering efficient desludging of wastewater lagoons. The minimal footprint requirements of the equipment profile make it an ideal solution for sites that have challenging site constraints.

Successful Partnership with TDG and client in delivery of Sewer Bypass in Queensland

Cleaning of one of the largest pump stations in Brisbane, handling all waste from the S1 trunk main.

TDG was contacted about using our high-pressure robotic cutter to remove concrete slurry that had entered a 375mm trunk sewer main during construction. Another contractor had started the process of removing the concrete deposit but their robotic milling unit was proving to be ineffective and as a result an alternative methodology was needed.