A regional road in South Australia required urgent structural repairs after a large sinkhole developed above three 1800mm culverts beneath the roadway, a key route for grain haulage.

A regional council in northern New South Wales required a comprehensive inspection and condition assessment of its stormwater network to strengthen flood mitigation planning and inform future maintenance priorities.

A tidal channel in Sydney required the removal of asbestos-contaminated sediment to restore environmental safety and site integrity. The site presented complex conditions including limited access, tidal fluctuations, and a 1.4km haul route from the entry point. TDG Environmental was engaged by the client to deliver a compliant and efficient solution for safe waste removal, stockpile management, and site rehabilitation within a restricted tidal environment.

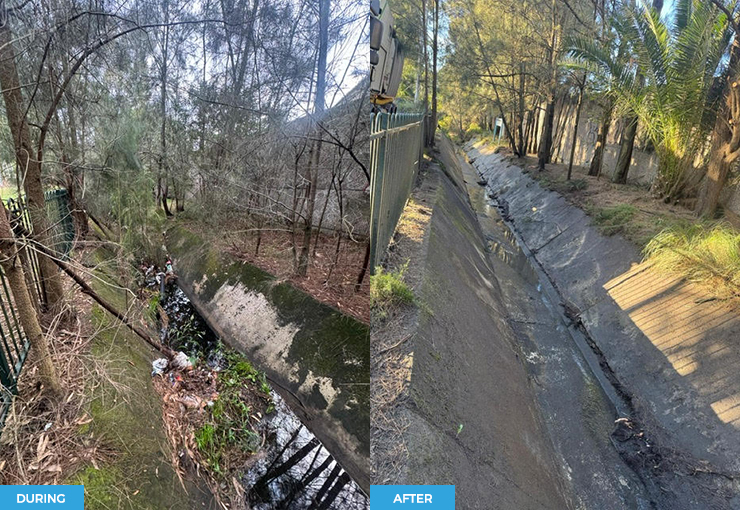

A canal in Sydney required vegetation removal and desilting works to restore proper water flow and reduce the risk of flooding during heavy rainfall. The site presented significant access challenges, including no ramp access and extremely tight working conditions. TDG Environmental was engaged to provide a solution that would overcome these limitations while ensuring safe and efficient removal of overgrowth and built-up sediment.

A heavily overgrown canal in Western Sydney required urgent desilting and vegetation removal to restore water flow and reduce the risk of flooding. Due to the steep embankments and absence of ramp access, traditional excavation methods posed significant safety risks. TDG Environmental was engaged to deliver a safe, efficient, and non-entry solution to clear the canal and prevent future blockages.

TDG Environmental successfully rehabilitated the sewer pipeline, achieving a fully sealed and structurally reinforced solution. The intervention prevented potential sinkholes, safeguarded the roadway, and ensured the long-term reliability of the asset.

A newly placed power pole was installed through an existing asset, causing a major obstruction and presenting a potential flood risk. The issue required a rapid and comprehensive intervention to prevent further damage and ensure the continued functionality of the affected infrastructure.

A severe sewer blockage obstructed 99% of a 1075mm diameter pipe located 30 metres underground, requiring urgent and complex intervention over a 2.5-week period.

Engaged to assist in flood recovery efforts for a regional council area, we set out to clean debris from 9 x 825mm pipes, including their inlets and outlets. Services provided: Kaiser Water Recycling Unit to allow for continuous cleaning operations, despite there being no onsite water An excavator and tipper to remove excess debris Traffic control measures to safely isolate the site from vehicle traffic A locator to identify underground assets, preventing any potential damage

The project’s main goal was to conduct lateral lining installations within wastewater connections, a task requiring a high degree of expertise and precision. Our team met this challenge with remarkable proficiency, delivering outstanding results that surpassed expectations.

TDG was engaged for assessment and rectification of 4.5 kilometers of Stormwater conduit and maintenance holes, utilising CCTV inspections or physical traversing methods, followed by necessary rectification works.

TDG was engaged to pressure clean and record data from pressure drains at the base of the Dam wall and spillway. The drains provide important pressure release role in operation of the dam to mitigate destabilising pressure in the structure.

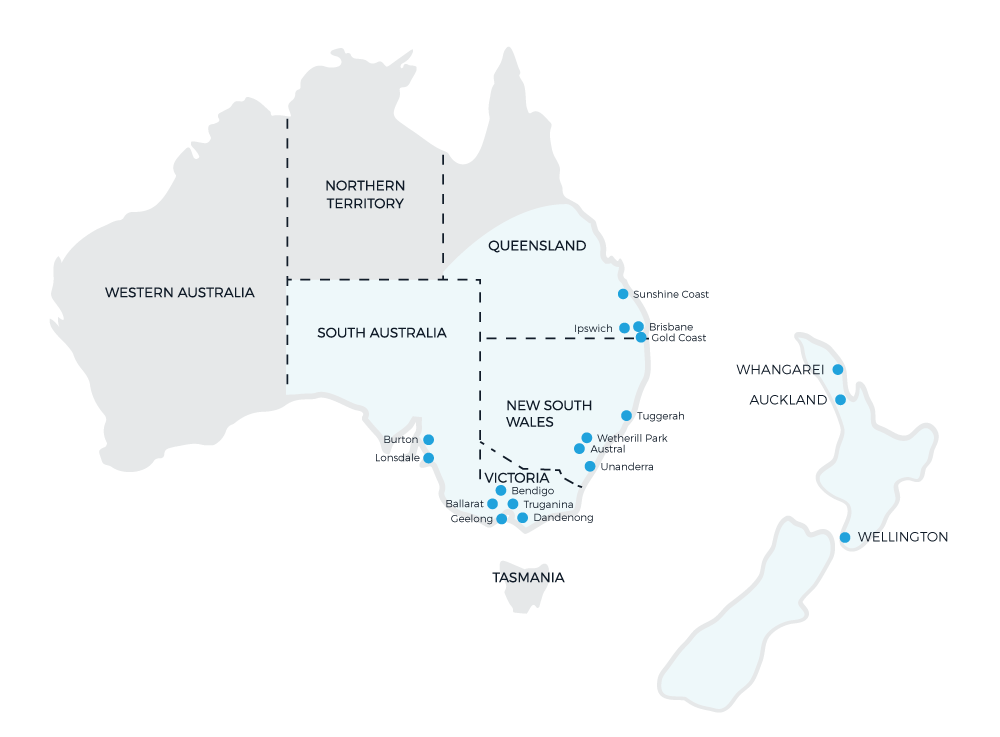

This project aimed to assess silt levels within a 2.4km, 1200mm ocean outfall from the primary wastewater treatment plant to the ocean discharge using a sonar-equipped, neutrally buoyant sub from the MSI toolkit. A specially trained 5-person crew traveled from Auckland to Timaru over two days for the inspection, as the outfall, initially inspected in 2013, showed a significant silt buildup resulting in a 25% reduction in diameter. Reengaged after 10 years, TDG was tasked to conduct a follow-up inspection to assess the effectiveness of the Council’s cleaning program required by the discharge consent.

TDG delivered a comprehensive and organised solution to fulfill the client’s specified works scope, involving coordination with various contractors such as locators, traffic management, and surveyors, while navigating through multiple jurisdictions and permits including those from local government, Department of Transport, and resident notifications.

The client engaged TDG to carry out smoke testing as a proactive measure to identify and address leaks and defects in sewer systems. The local pump station for council has recorded more water going through then what is scheduled capacity. Through the implementation of smoke testing, TDG successfully pinpointed areas of concern within their sewer infrastructure, leading to targeted repairs, improved system integrity, and enhanced environmental protection.

The client engaged TDG to conduct an investigation into a pipeline connected to a drainage tank for a Community Centre, which experienced surcharge and flooding during heavy rainfall. Through CCTV investigation, we identified the pipeline obstruction caused by large tap roots and masses. Subsequently, TDG was tasked with restoring the pipeline to its full structural integrity and serviceability.

The project in Wellington involved TDG Environmental using Multi-Sensor Inspections (MSI) to profile interceptor corrosion, resulting in the discovery of rapid degradation, demonstrated through a comparison report spanning 2013 to 2020, highlighting the need for ongoing inspections and leading to client satisfaction and pipeline relining.

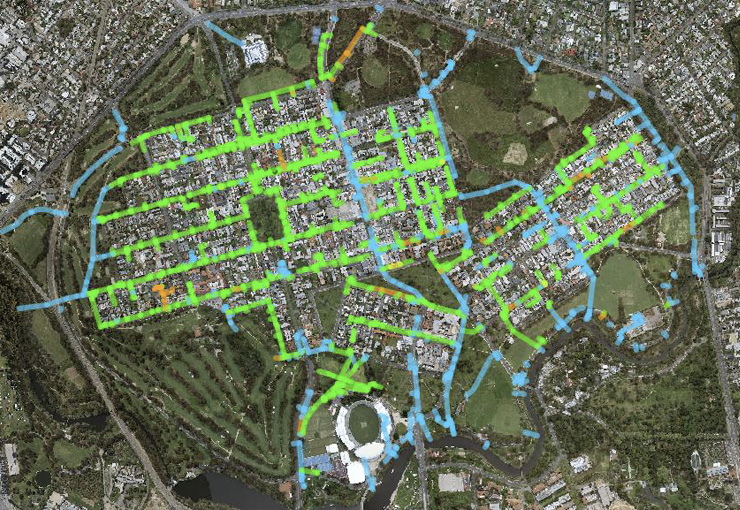

TDG was tasked by the client to conduct comprehensive data collection within the project’s catchment area to evaluate network conditions and renewal needs. This involved employing various techniques, including CCTV inspections, laser profiling, and GPS surveying.

The successful removal of a submerged car from creek in Sydney NSW, conducted by experienced contractors via crane while ensuring minimal environmental impact and implementing traffic control for public safety, resulted in a safely accessible site following completion of fencing repairs and car removal.

TDG provided liquid waste removal services for the 2023 Airshow, managing the largest attendance in the event’s history; approx 20,000 per day during the trade days and 80,000 people per day during the general public days. With 8 vehicles strategically stationed on site, we removed over 710,000 litres of liquid waste throughout the event.

The project involved meticulous organisation and execution of traffic management plans, including MOAs and TGS, as well as hydro excavation to expose services and utilities for service proving. Close collaboration with surveyors facilitated accurate service proving, while careful attention was paid to reinstating surfaces to their original condition.

Client engaged TDG to assist with grease removal using a Class B pump for water blasting. After years of grease buildup in the sediment tank, it was deemed unsafe for the contractor to perform any hot works. TDG entered the confined space and removed all hot work hazards using high-pressure water blasting and emulsified grease down to run back through the treatment plant.

Client engaged TDG to assist with a major sediment removal and rectification works project for multiple On-Site Detention Basins within an Airport in NSW. These OSDs had suffered years of neglect and were contributing to localised flooding in major rain events.

Faced with an extremely challenging culvert, this historic brick arch required precision and caution due to its fragile nature, susceptible to damage if mishandled. TDG Environmental was tasked with cleaning out the culvert chamber, measuring nearly 30m in length and 2m in width.

TDG Environmental was reached out by a local council to clean and clear the blockages at the inlet. The client was also aware that we were unable to clear the blockages without Ultra High-Pressure Water Blasting (UHPWB).

Stormwater Survey, Inspection and Condition Assessment of the entire North Adelaide Storm Water network

TDG’s unmanned (remote operated) dredge is unmatched when it comes to delivering efficient desludging of wastewater lagoons. The minimal footprint requirements of the equipment profile make it an ideal solution for sites that have challenging site constraints.

Successful Partnership with TDG and client in delivery of Sewer Bypass in Queensland

Cleaning of one of the largest pump stations in Brisbane, handling all waste from the S1 trunk main.

TDG was contacted about using our high-pressure robotic cutter to remove concrete slurry that had entered a 375mm trunk sewer main during construction. Another contractor had started the process of removing the concrete deposit but their robotic milling unit was proving to be ineffective and as a result an alternative methodology was needed.

Australia 1300 330 294

Australia 1300 330 294